PM Krupp utilizes powdered metal compaction and sintering of high-speed and other tool steels in open die part configurations. What we offer our customers:

Benefits of PM Krupp processing

- Capturing net and near net shapes of difficult to machine materials high chip value (unlike machining there is little or no material loss in processing high speed steel materials into complex shaped parts).

- Excellent Surface Finishes

- Good tolerance control abilities

- Best suited to medium and high-volume production

- Can be coated with all standard wear resistant coatings (TiN, TiAlN, TiCN, DLC etc)

- Compared to conventional high-speed steel PM Krupp materials have

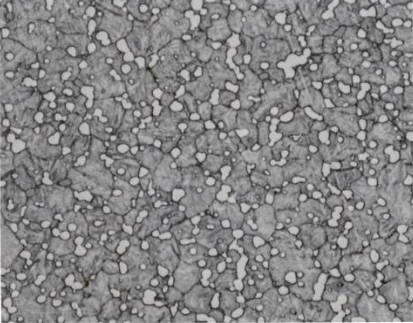

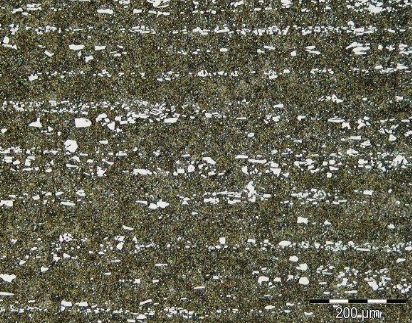

- Refined microstructure – freedom from large scale segregation

- Isotropic properties (properties the same in all directions)

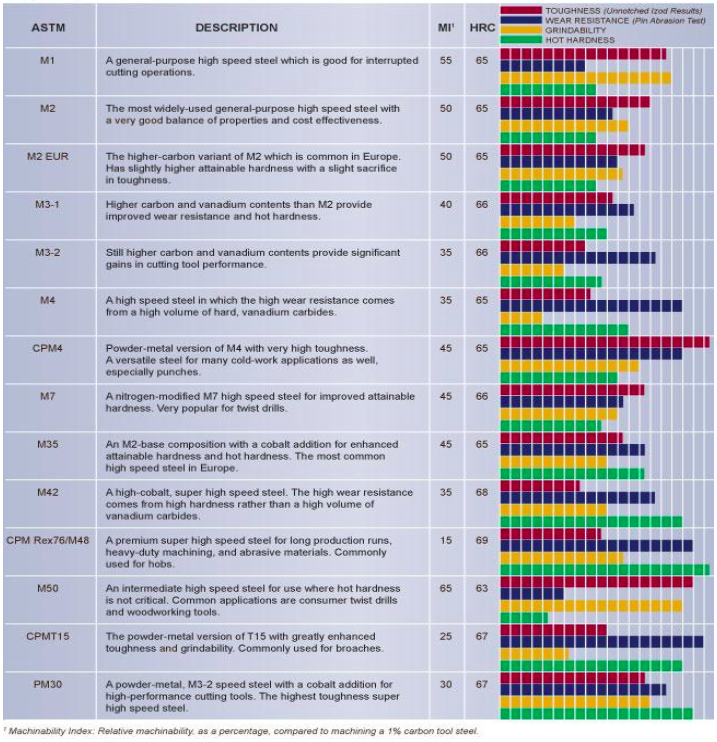

- Higher machinability/grindability

- Improved toughness

- Reduced distortion and more consistent response during heat treating.

- Superior wear resistance

These improved properties allow our customers to realize increased productivity due to:

- Less downtime changing cutters and inserts

- Faster speeds and feeds

- Longer tool life

Design considerations: Shapes are limited to open die configurations. Parts require finish grinding for a cutting edge.