[fa icon="plus-square"] What are some parameters for lathe turning?

Tool Geometry: 0-5 degree negative back rake, 5 degree side rake, .030"

- Tool Material: Tungsten Carbide (C-5 Class or better)

- Tool Setting: Slightly below center

- Depth of Cut: .050" to .100"

- Feed: .003" to .012" per revolution

- Cutting Speed: 35 sfm

- Coolant: None

[fa icon="plus-square"] What are some parameters for milling?

Tool Material & Type: Solid or brazed insert cutters - Use High Speed Steel/Cobalt or Tungsten Carbide with a tool geometry of a general purpose type. For Indexable Insert Cutters: Use Tungsten Carbide (C-5 Class or better) Tool geometry should be a double negative rake with a large lead angle.

- Depth of Cut: .010" to .050"

- Feed: .003" to .012" per cutting edge per revolution

- Cutting Speed: 35 sfm

- Coolant: None

[fa icon="plus-square"] What is the heat treat cycle?

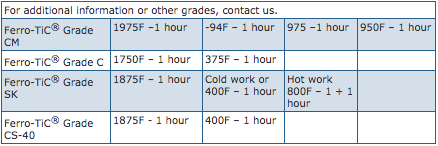

The chart below defines the heat treat cycle by grade: