We Make Our Own Carbide Products

We press and sinter in our own plant. By making our own carbide we can control the quality, price and delivery schedule.

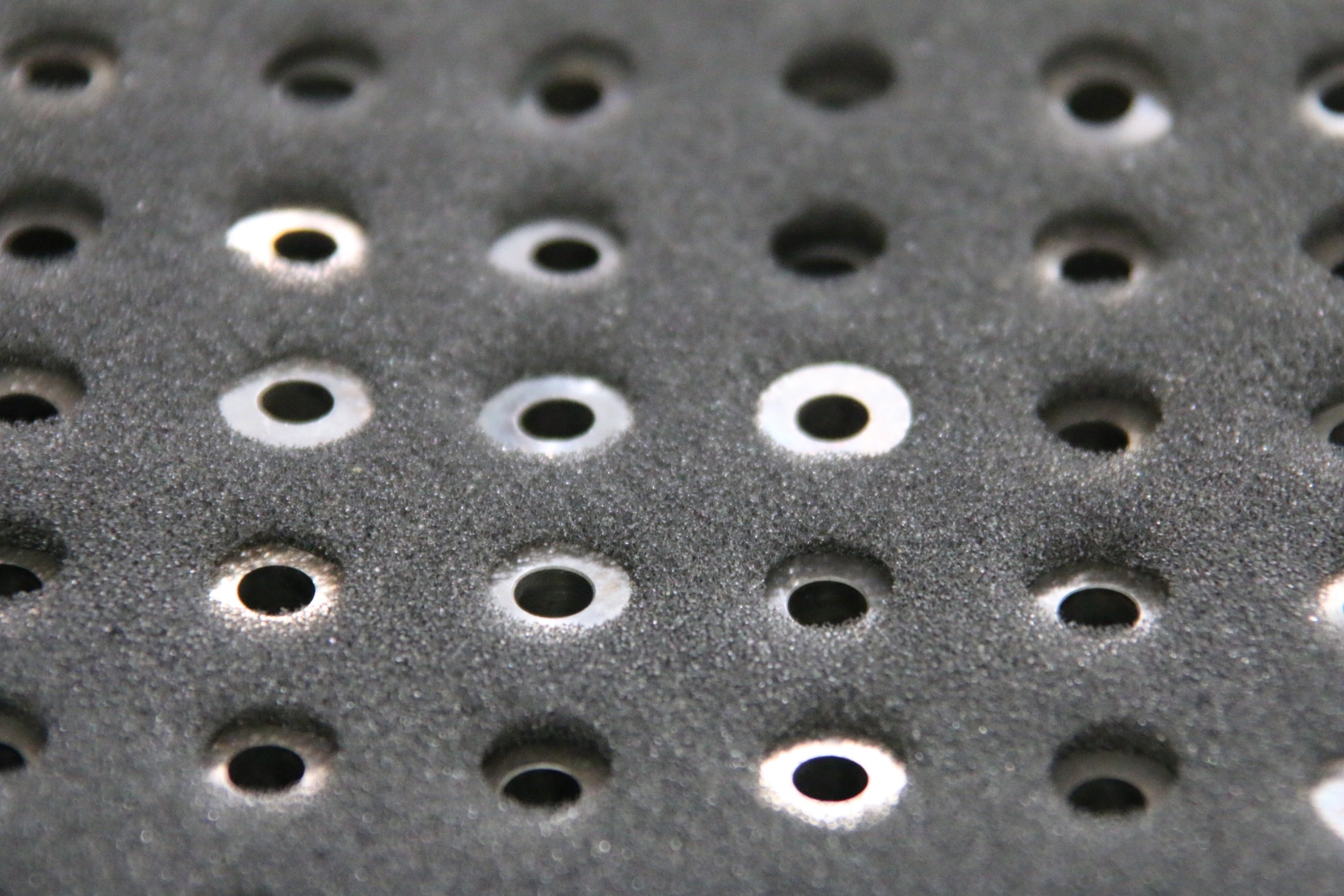

How Cemented Carbides are Made at Yillik

Carbides are made by blending micron-sized tungsten carbide particles with Cobalt (or Nickel) powders. This mixture is placed in a mold and compacted to a net or near net shape. Green machining in the as-compacted state can be performed for added shape complexity and then this pre-form is sintered at a temperature that is high enough to allow the Cobalt to melt. As the Cobalt flows it coats or wets each grain. When the Cobalt cools it solidifies cementing the grains together forming a composite. Cemented Carbides get their hardness from the Tungsten Carbide grains and their toughness from the bonding produced by the cementing action of the Cobalt metal. By varying the amount of Cobalt we can change the hardness, wear resistance, and toughness (shock or impact resistance) of the carbide to provide optimum performance for your specific application.