Our Expertise in Metal Injection Molding

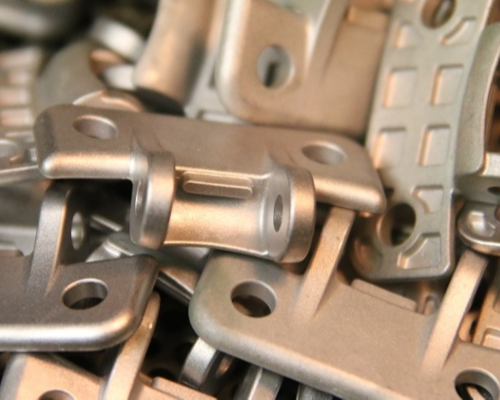

Metal Injection Molding (MIM) is a versatile manufacturing process that merges plastic injection molding with metal powder metallurgy. At PSM Industries, we leverage advanced MIM technology to create complex geometries that traditional methods can't achieve.

Our skilled engineers collaborate closely with clients to develop tailored solutions that meet and exceed industry standards. By optimizing the MIM process, we ensure high precision and quality, resulting in reliable components.

MIM is ideal for producing intricate parts with tight tolerances, making it suitable for aerospace, automotive, medical, and consumer goods. This process minimizes waste through the use of metal powders, reducing production costs and environmental impact. Our advanced equipment also allows for efficient large-volume production, ensuring timely delivery to our clients.

PSM Industries consists of eight different divisions throughout the US.

Pacific Sintered Metals

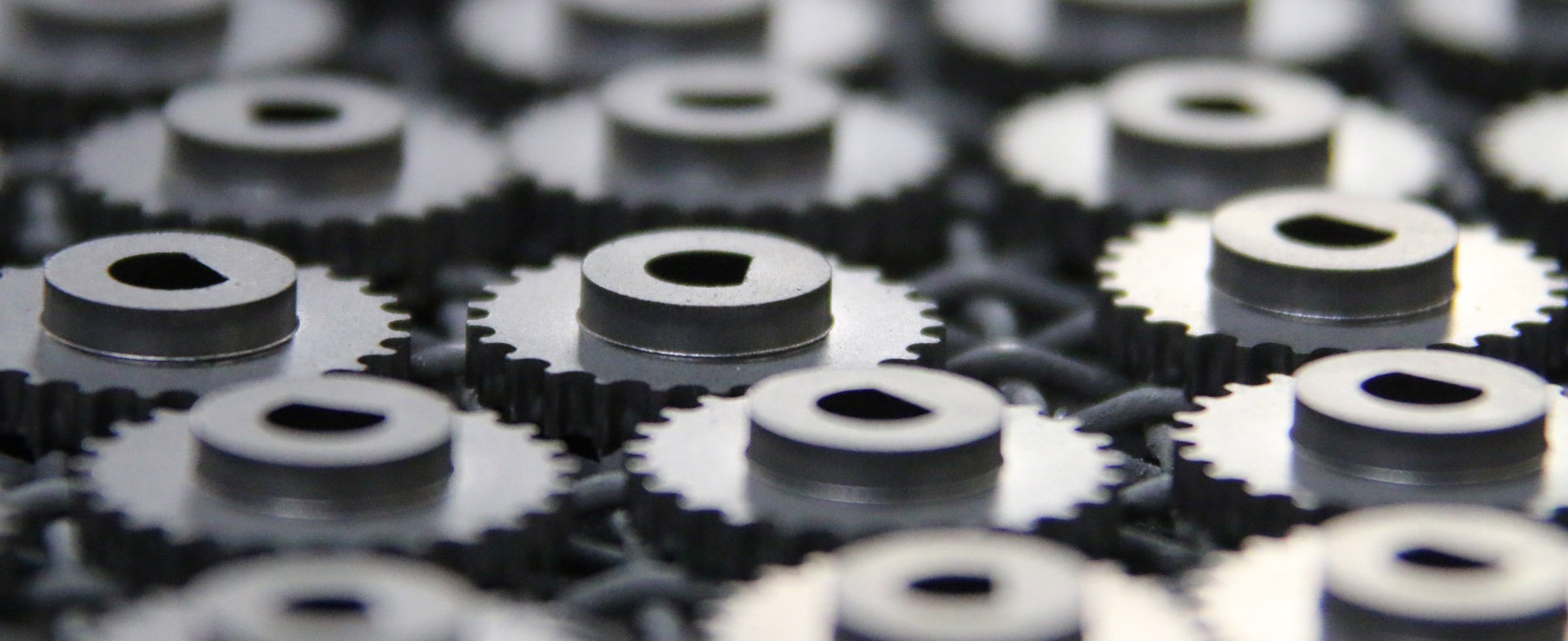

At Pacific Sintered Metals, we specialize in advanced metal powder metallurgy processes. Our metal sintering capabilities enable the creation of high-quality components that meet the rigorous demands of various industries. By selecting and processing metal powders carefully, we achieve superior material properties, including enhanced strength, wear resistance, and corrosion resistance.

Our metal sintering process involves heating metal powders just below their melting point, allowing them to bond and form solid components. This method is especially advantageous for producing complex shapes that are difficult to machine from solid metal. Our sintered parts are widely used in automotive applications, providing durability in critical components like gears and bearings. We also supply sintered components for various industrial machines, enhancing their efficiency and longevity, and our expertise extends to the consumer goods sector, where we meet both aesthetic and functional requirements.

PM Engineered Solutions

At PM Engineered Solutions, we focus on providing customized manufacturing solutions through our expertise in metal injection molding (MIM). Our experienced team collaborates with clients to develop tailored products, ensuring optimal performance. We emphasize a consultative approach, working closely with clients from initial concept to production, addressing every detail.

This commitment to customization distinguishes us in the industry, allowing us to deliver innovative solutions that enhance our clients' competitive advantage. Our tailored designs cater to sectors including automotive, aerospace, and medical devices, where precision is critical. We also offer rapid prototyping services to test and validate designs before full-scale production. Utilizing our MIM technology, we produce high-quality components at competitive prices, reducing overall project costs.

BestMetal

BestMetal is dedicated to excellence in manufacturing, utilizing MIM to produce reliable components for various applications. Our rigorous quality assurance measures ensure that every product meets the highest performance standards. Our experienced team monitors the production process continuously, implementing best practices to maintain consistency.

This dedication to excellence has established our reputation among metal injection molding companies. Our components are vital in the aerospace industry, where safety is paramount. Also, our precision-engineered parts serve the medical device sector, ensuring reliability in critical applications, and we supply high-quality components for electronic devices, enhancing their functionality.

PolyAlloys

PolyAlloys offers a diverse range of products developed through advanced metal powder metallurgy techniques. Our focus on innovation allows us to enhance material properties and deliver superior solutions for our customers. By utilizing various metal powders, we create components optimized for specific applications, meeting demanding standards.

Our sintered products are ideal for tooling applications, providing durability and precision. We cater to industries by supplying components that improve the efficiency and performance of industrial equipment. Our advanced materials are also used in wear parts, ensuring longevity in demanding environments.

PM Krupp High Speed Steels

At PM Krupp High Speed Steels, we specialize in producing high-performance steel components that meet the demanding requirements of various industries. Our expertise in metal powder metallurgy allows us to create materials that provide exceptional hardness and wear resistance, ideal for cutting tools and industrial applications.

We focus on delivering tailored solutions that enhance operational efficiency and product longevity. Our commitment to continuous innovation ensures we remain at the forefront of steel manufacturing technologies, supplying high-speed steels that contribute to our clients' success in aerospace, automotive, and manufacturing sectors.

Yillik Precision Carbides

Yillik Precision Carbides is dedicated to high-quality carbide components essential for industrial applications. Manufactured using advanced metal sintering techniques, our products ensure exceptional performance and durability. We serve industries requiring precision components, such as aerospace and oil and gas.

Our carbide products are known for excellent wear resistance, making them suitable for cutting tools and dies. At Yillik, we strive to meet the evolving needs of our clients, delivering solutions that enhance productivity and efficiency.

W.M. Gulliksen

W.M. Gulliksen provides a comprehensive range of metal components tailored to our customers' diverse needs. Our expertise in metal injection molding enables us to deliver high-quality products for various applications. We serve industries including automotive, medical, and consumer goods, where reliability and performance are paramount.

Our commitment to quality and customer satisfaction drives us to improve our processes continuously, ensuring we remain a trusted partner in the manufacturing sector.